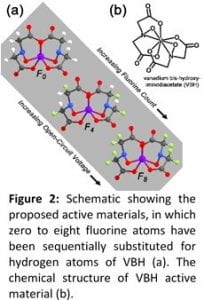

Design of flow battery active material for Redox Flow Batteries (Dr. Patric Cappillino)

Students would synthesis and characterize next-generation flow battery active materials, building on a family of redox active molecules developed in the Cappillino lab. This would involve synthetic techniques, spectroscopy, and crystallography. In cooperation with a senior graduate student, these active materials would also be electrochemically characterized for use in advanced batteries.

Students would synthesis and characterize next-generation flow battery active materials, building on a family of redox active molecules developed in the Cappillino lab. This would involve synthetic techniques, spectroscopy, and crystallography. In cooperation with a senior graduate student, these active materials would also be electrochemically characterized for use in advanced batteries.

Booster Materials for redox-targeting flow batteries (Dr. Cappillino)

Students would prepare so-called Prussian Blue Analogs for use in hybrid, flow/solid-state batteries. These are a class of insoluble materials with one or more metal ion(s) in a lattice, which can be tuned to alter electrochemical properties. Their use, in combination with conventional, solution-phase flow batteries, is a promising strategy to overcome energy density limitations. These compounds would be synthesized and characterized spectroscopically and electrochemically.

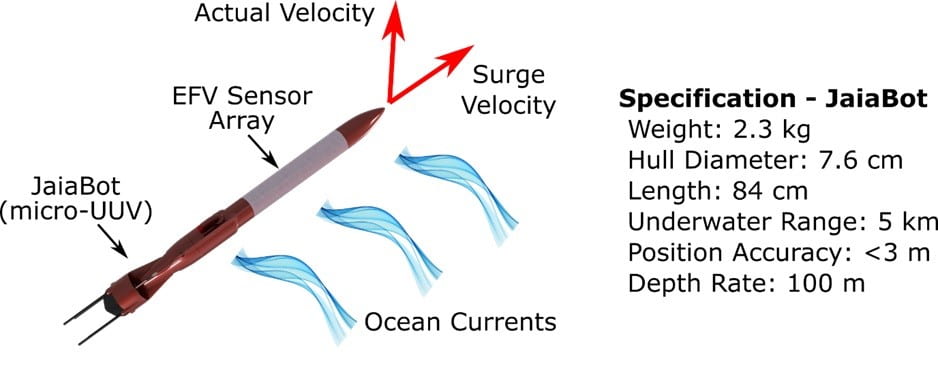

Cost-effective Elastic Filament Velocimetry (EFV) Sensor for Small Unmanned Underwater Vehicles (UUVs) (Prof. Kihan Park)

The project aims to develop a cost-effective, lightweight, drift-free, self-contained, standalone sensor network using elastic filament velocimetry (EFV) for real-time identification of velocity and pose of small unmanned underwater vehicles (UUVs) in 3-dimensional space. Accurate real-time velocity measurement of UUVs is an essential capability for successful undersea navigation, especially when without the help of a global positioning system (GPS). We will fabricate the submersible sensor in MIT’s Fab.nano facility and an REU student is expected to take an independent role in this project regarding one of the following tasks: design / fabricate / characterize / testing the sensor in various fluidic environments.

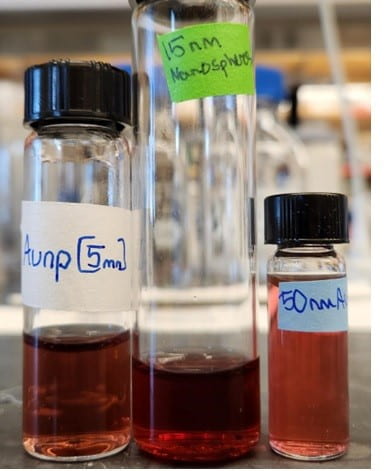

Plasmonic Materials for Tunable Optical Camouflage (Dr. Wei-Shun Chang)

Optical camouflage has been widely deployed in the military to reduce the visibility of weapons and soldiers to potential thread. The currently deployed technologies rely on the passive camouflage technique, which adapts the color and texture of the combat units to the known environment. However, the passive camouflage is not functional when the local background changes. In the Chang lab, we will synthesize the plasmonic nanoparticles that exhibit large absorption and scattering cross-sections. The color of the nanoparticles can be tuned by their sizes, shapes, compositions, and surrounding environment. We will integrate the nanoparticles into an electro-optical device to achieve active control of the color change, which is the first step to realizing the tunable optical camouflage.

Novel bi-functional composite materials for structural energy storage in marine systems (Dr. Caiwei Shen)

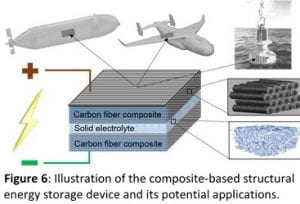

An increasing number of electrically powered marine systems such as distributed sensors and autonomous underwater vehicles (AUVs) are being deployed in the oceans. The operation time, useful lifetime, and the overall size of such systems are still limited by the energy storage components (e.g. rechargeable batteries) that provides the power. Meanwhile, polymer matrix composite (PMC) materials are widely used as structural components in all kinds of naval systems partly due to their outstanding mechanical properties, lightweight and durability. Here we aim to develop novel bi-functional composites (shown in Figure 6) that integrate energy storage functionality into structural PMC for maritime applications. Previous studies have demonstrated structural supercapacitors, which is an electrochemical energy storage device, using ion-conducting resin as electrolytes and carbon fibers as electrodes. Supercapacitors outperforms batteries in terms of safety, stability, and operation lifetime. However, the reported devices show limited energy densities (<10 mWh/kg). Shen has worked on carbon fiber-solid electrolyte supercapacitor systems in the past years. Our work demonstrated gel electrolyte and activated carbon fiber electrode with more than two orders increase in energy and power densities (1-3 Wh/kg @ 10-100 W/kg), but the gel electrolyte/carbon fiber composite is not stiff enough for structural applications. The proposed project will experiment and design the synergistic electrochemical and mechanical effects of the bi-functional electrode-electrolyte systems. Our hypothesis is that the mechanical properties and energy storage performance of such composites can be tuned by adjusting the chemical composition of the electrolyte matrix and the surface property of the electrode filler. The intellectual merit is to understand the bi-functional interfaces in composites and design materials with practical energy and power densities (~10 Wh/kg @ 100 W/kg) and improved mechanical toughness. The broader impact is to provide a novel solution to improving the power supplies of all kinds of consumer, military, and space applications, by storing electricity in their structural frameworks.

An increasing number of electrically powered marine systems such as distributed sensors and autonomous underwater vehicles (AUVs) are being deployed in the oceans. The operation time, useful lifetime, and the overall size of such systems are still limited by the energy storage components (e.g. rechargeable batteries) that provides the power. Meanwhile, polymer matrix composite (PMC) materials are widely used as structural components in all kinds of naval systems partly due to their outstanding mechanical properties, lightweight and durability. Here we aim to develop novel bi-functional composites (shown in Figure 6) that integrate energy storage functionality into structural PMC for maritime applications. Previous studies have demonstrated structural supercapacitors, which is an electrochemical energy storage device, using ion-conducting resin as electrolytes and carbon fibers as electrodes. Supercapacitors outperforms batteries in terms of safety, stability, and operation lifetime. However, the reported devices show limited energy densities (<10 mWh/kg). Shen has worked on carbon fiber-solid electrolyte supercapacitor systems in the past years. Our work demonstrated gel electrolyte and activated carbon fiber electrode with more than two orders increase in energy and power densities (1-3 Wh/kg @ 10-100 W/kg), but the gel electrolyte/carbon fiber composite is not stiff enough for structural applications. The proposed project will experiment and design the synergistic electrochemical and mechanical effects of the bi-functional electrode-electrolyte systems. Our hypothesis is that the mechanical properties and energy storage performance of such composites can be tuned by adjusting the chemical composition of the electrolyte matrix and the surface property of the electrode filler. The intellectual merit is to understand the bi-functional interfaces in composites and design materials with practical energy and power densities (~10 Wh/kg @ 100 W/kg) and improved mechanical toughness. The broader impact is to provide a novel solution to improving the power supplies of all kinds of consumer, military, and space applications, by storing electricity in their structural frameworks.

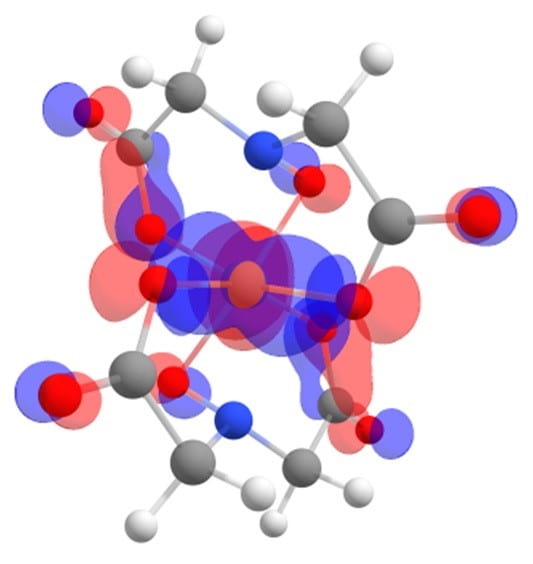

Accelerating Materials Discovery for Energy Storage Applications (Prof. Maricris Mayes)

Achieving a fully renewable energy landscape is contingent upon advancement of grid-scale energy storage technologies, and non-aqueous redox flow batteries (NRFBs) emerge as promising candidates. However, current lead-candidate redox-active materials for NRFBs have limitations such as low solubility, impaired transport properties, and low reduction potentials. Moreover, due to the vast chemical design space available, the traditional synthetic approach to developing high-solubility redox-active materials is costly and time-consuming. To tackle these challenges, the Mayes group aims to develop a robust computational framework for efficient in silico screening of redox-active materials, integrating quantum mechanics, molecular dynamics, and machine learning methods. The objective of this project is to understand the relationship between chemical structure of redox-active materials and their function as NRFB materials. Completion of this aim will contribute to designing new molecules for NRFB systems with optimal electrochemical properties. These fundamental studies would provide information on how molecular properties determine macroscopic properties that give rise to specific performance aspects of advanced battery electrolytes.

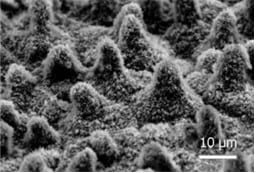

Fabrication and Characterization of Superhydrophobic Surfaces by 3D Printing (Prof. Hangjian Ling)

Superhydrophobic surface (SHS) has received growing attentions in recent years due to its wide engineering applications, from preventing underwater surface from corrosion, icing and biofouling, to reducing the energy cost and greenhouse gas emission for maritime transportation. SHS, initially found on lotus leaves and animal skins, is best known for their water-repellent and self-cleaning properties. It has a large water contact angle (>150°) and small contact angle hysteresis (<10°). Generally, SHS is created through a combination of surface roughness and hydrophobic chemistry. Over the past two decades, various techniques have been developed to fabricate artificial SHS, including ‘top-down’ (e.g., lithography, chemical etching, plasma etching, micro-machining) and ‘bottom-up’ methods (e.g., chemical vapor deposition, spray coating, dip coating, spin coating). However, most previous techniques cannot produce SHS at low cost and fast speed. The goal of this project is to explore the capability of a resin-based 3D Printer to create SHS with well-organized surface textures and a texture size of 100 to 300 micrometers. The fabricated SHS will be evaluated by scanning electron microscopy, high-speed imaging, pressure tests, flow tests and etc. If success, this project will provide an alternative method to produce SHS at low cost and fast speed.

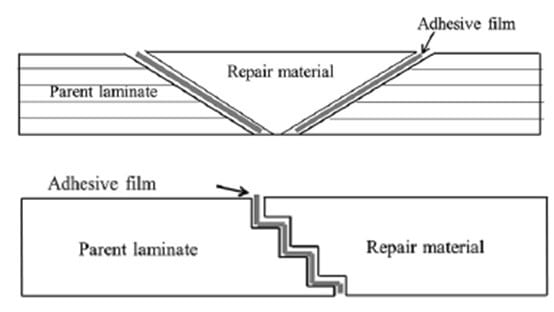

Damage sensing studies in repaired intra-ply laminate composites (Prof. Vijay Chalivendra)

Outstanding properties of fiber reinforced polymer composite materials, lead to a wide application in all the sectors such as aerospace, automotive, marine, sports industries and even in the civil infrastructures, etc. Since the last decades, an enormous use of composite materials in the aerospace sector has caused an increasing need for repair technology of damaged component rather than replacement with a new component. In this study, we will investigate damage sensing characteristics of these repaired composites under tensile, bending conditions using novel four-circumferential probe technique. The piezo-resistance change due to damage evolution in repaired composites will be connected with scanning electron microscopy images of fracture surfaces under above loading.

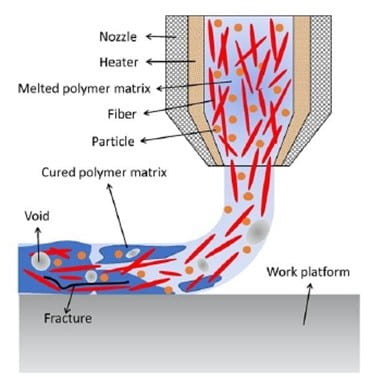

Dynamic fracture characterization of 3D printed polymer composites (Prof. Vijay Chalivendra)

This project is aimed to understand the fracture toughness of 3D printed polymer composites under impact loading conditions. The composites will be printed with fusion deposition modeling (FDM) printer using Acrylonitrile butadiene styrene (ABS) filled with carbon fibers filament. The three-point bending specimen configuration will be used to investigate the fracture toughness. A modified split Hokinson pressure bar in conjunction with a high-speed video camera (with framing rate of 100 millions frames/second and exposure time of 50ns) will be used to investigate the crack dynamics under impact wave loading. The high speed data acquisition will be used to capture the load-displacement data to determine dynamic fracture initiation toughness of the composites under mode-I and mixed-mode loading conditions.

Microbial valorization of lobster shell chitin (Prof. Chris Brigham and Tracie Ferreira)

A microbial system will be developed to isolate and break down chitin from lobster shells. Microbial culture methods will be used first to isolate chitin polysaccharide from the shells and then to break down the chitin into monosaccharides. The monosaccharides can then be used to feed different microbial cultures to make bio-based, value-added products like biofuels or bioplastics.The work addresses the following areas of interest: (1) biologically based purification of chitin biomaterial from waste lobster shells, (2) metabolic conversion of chitin to fermentable carbon source for bioconversions, (3) conversion of waste carbon source to value-added product (biodiesel precursor). Tools used in this study include: sterile technique, microbial culture methods, biomaterial purification methods, upstream and downstream processing methods.

Understand The Longevity of Superhydrophobic Surfaces in Marine Environment for Next-Generation of Anti-Biofouling Materials (Prof. Hangjian Ling)

Marine biofouling, defined as the accumulation of micro-organisms on ocean-submerged surfaces, produces adverse impacts on the unprotected vessels, naval fleets, offshore infrastructures, and undersea sensors. Effective biofouling protection can save the global maritime industry of about 150 billion US dollars per year. Recently, the Super-Hydrophobic Surface (SHS), which mimics the properties of lotus leaves, mollusks shells, and shark skins, provides exciting opportunities to prevent marine biofouling. By entrapping a thin layer of gas bubbles within the micro/nano-scale surface textures, the SHS protects solid walls against directly contacting with liquid and micro-organisms. However, the gas cushions on SHS might be destroyed in marine environment by turbulent flows or gas diffusions, deteriorating the efficiency of anti-biofouling. This study aims to understand the longevity of superhydrophobic surfaces in marine environmental. Various types of SHSs will be fabricated by 3D printing, laser texturing, and sandblasting. The longevity of fabricated samples will be studied in undersaturated water. A high-speed camera will be used to measure the status of air on the fabricated samples. If success, this project will develop the next-generation of anti-biofouling materials.